CJ 시리즈는 주로 다양한 유형의 에어컨 파이프라인의 알루미늄 합금 부품을 레이저용접하는 데 사용됩니다.

모델 :

CJ2000전원공급장치 :

380V직선 축 포지셔닝 정확도 :

0.1mm/m"직선축 재배치 정확도" :

0.06mm레이저 파워 옵션 :

2000WY축 이동 :

350mm전력 위상 수 :

3+N+PEZ축 이동 :

300mm빈도 :

50HzP축 이동 :

150mmB1축 이동 :

N*360°B2축 이동 :

N*360°용접 공정 :

Laser wire fill welding워크스테이션 :

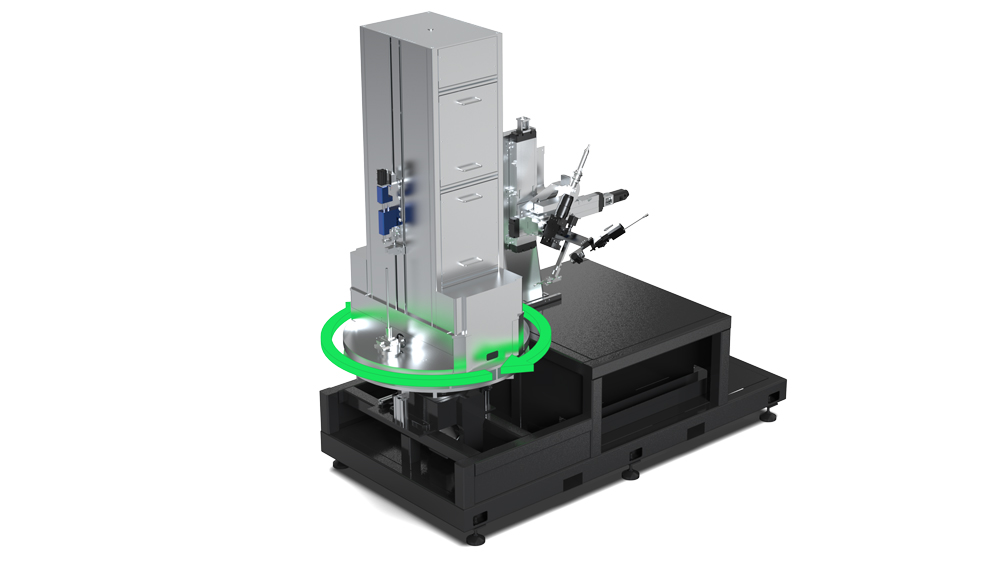

2CJ 시리즈 레이저 용접기

CJ 시리즈 레이저 용접기는 1대 N 설계로 레이저 활용도를 높일 수 있습니다. 완전 서보 구동이며 고정밀성을 특징으로 하여 에어컨 파이프라인의 다양한 연결 용접을 용접할 수 있습니다. 완전한 세트의 Omron 레이저 용접 제어 시스템을 갖추고 있으며 정밀한 와이어 공급 기능이 있습니다. 가공 스테이션은 구조가 컴팩트하고 바닥 면적이 작습니다.

특징

듀얼 스테이션 워크벤치

듀얼 스테이션 회전 작업대를 장착한 회전 구동 메커니즘은 가변 주파수 모터로 구동되는 캠 디바이더로 구동됩니다. 작업대는 두 개의 서보 모터와 고정밀 행성 감속기로 구동되는 회전 샤프트를 갖추고 있습니다. 회전 샤프트의 설계에는 작업물 침지 요구 사항에 대한 고려 사항이 통합되어 용접 구성 요소의 다양성이 향상됩니다.

Y/Z/P 축 모션 모듈

선형 모션 축의 경우 모든 전달 구성 요소는 고성능 서보 모터로 구동되고 정밀 볼 스크류, 고정밀 리니어 가이드 및 기타 효율적인 전달 메커니즘이 장착되어 정확하고 안정적인 전달을 보장합니다. 리니어 레일 슬라이더에는 가이드 레일에서 이물질을 청소하기 위한 보호 스크레이퍼가 장착되어 있습니다. Y축 트랙에는 서비스 수명을 연장하기 위한 통합 아코디언 스타일 보호 커버가 있습니다. P축은 용접 헤드의 각도를 조정하기 위한 회전 축 역할을 합니다.

압축 시스템

더 광범위한 제품에 대한 적응성을 높이기 위해 리프팅 및 프레싱 시스템이 설계되었습니다. 리프팅 메커니즘은 서보 모터와 볼 스크류를 사용하여 툴링을 수직으로 구동하는 반면 실린더는 압축을 위한 액추에이터 역할을 합니다. 또한 이 장치에는 다양한 감지 기능을 용이하게 하는 여러 센서가 장착되어 있습니다.

1. 레이저 거리 센서를 설치하여 부품의 높이를 측정합니다.

2. 레이저 센서는 작업물 지지 상태를 모니터링하는 데 사용됩니다.

3. 프레싱 시스템의 최대 프레싱 높이는 650mm입니다.

샘플 절단

자격증